Contact us at (630) 820-5550 to see how we can make the difference in your business.

Capabilities

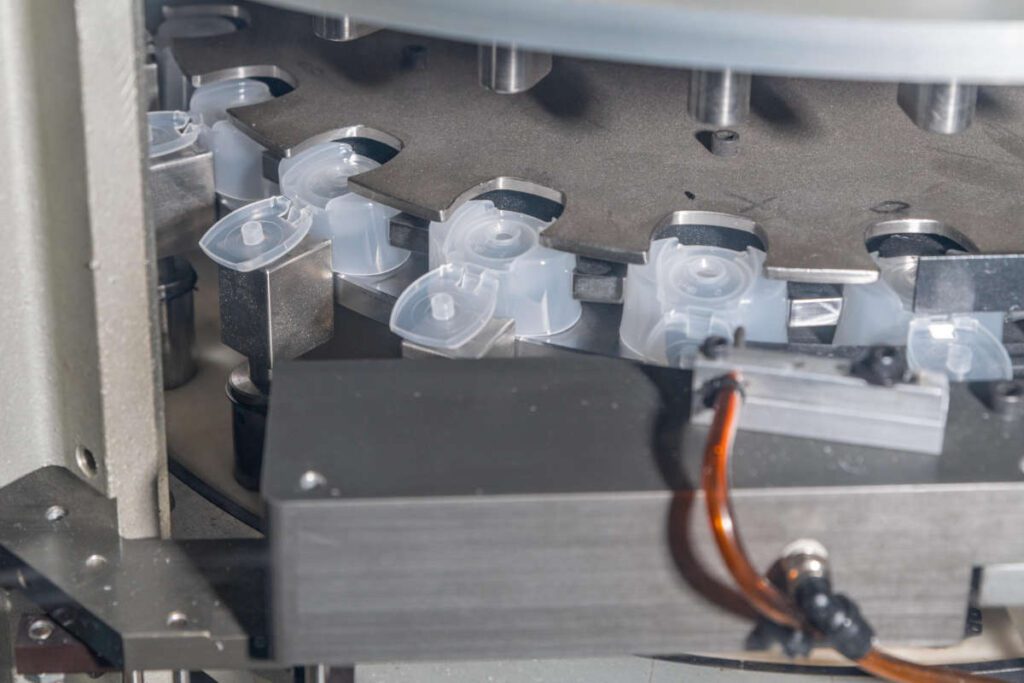

Assembly

At HQC, what began as a central resource for injection molding years ago has evolved into a full-service production facility that saves you steps, money and time in your manufacturing.

At HQC, what began as a central resource for injection molding years ago has evolved into a full-service production facility that saves you steps, money and time in your manufacturing.

Many customers have brought us a part for injection molding to be included in a sub-assembly for a larger product assembly. They are often pleased to discover that we can also provide many of the post-molding operations.

When you meet with us during the all-important concept review for a molded part, letting us know about your product’s exact assembly, packaging and use will ensure that we design the part to make it even more suitable for other stages of your manufacturing.

Having this knowledge can also allow us to make your process even more efficient and cost-saving by completing some or all of the plastics assembly during the injection molding. In these cases, we can work with you to develop automation and product assembly and packaging procedures as well as establish your quality requirements.

Services Beyond Injection Molding

Our services beyond injection molding can include overmolding, sonic-welding a component and even decorating the finished plastics assembly. With HQC, you have the resources to reduce warehouse storage, inventory tracking, assembly scrap and shipping costs according to your project objective.

HQC also can assemble multi-component parts and put them into a heat-sealed bag so they are ready for the customer. When your customer receives the product box, they need only tear open the bag for the parts that will complete the product they will use. A sub-assembly with tubing for a breast pump is but one example of how we can support a final assembly.

Your HQC concept review may reveal ways you can decrease your assembly time as well. This is especially true if it is during the molding procedure. Over time, HQC has become so proficient at product assembly and packaging that customers have brought their components to us for assembly alone without injection molding!

Whether you’re looking to install components in your injection-molded part, enhance a part for manufacturing or simply snap components together, contact us today to tell us about your project and discuss how our plastics and product assembly can help make your project more efficient and profitable.