Contact us at (630) 820-5550 to see how we can make the difference in your business.

Secondary Operations

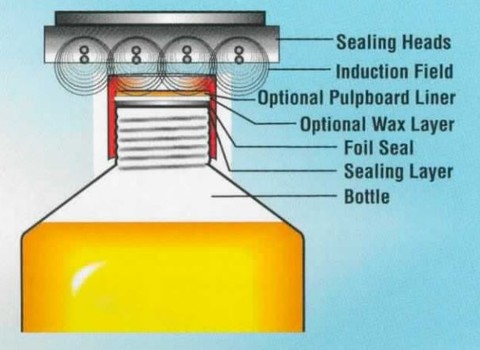

Induction Sealing

HQC’s versatile resources include induction sealing of liners for different types of closures. Induction sealing involves the application of a layer of foil to create a mating surface for the liner so when the cap is torqued down to the right setting it compresses the aluminum onto the plastic.

HQC’s versatile resources include induction sealing of liners for different types of closures. Induction sealing involves the application of a layer of foil to create a mating surface for the liner so when the cap is torqued down to the right setting it compresses the aluminum onto the plastic.

As the container or pouch fitment (weld spout) passes through the induction sealer, the foil is heated to melt with the sealant layer on the product’s contact surface, creating a hermetic seal. Induction sealing is a common method for reinforcing freshness and tamper evidence for food products and for medical products such as aspirin.

HQC has its own induction sealer that we can use for the liner depending on the size of the closure or container.

We developed this capability because in serving our customers as a closure and pouch fitment (weld spout) manufacturer, we wanted to further understand and support the other steps in manufacturing a customer’s product. Experience has taught us that some customers run into problems with induction cap sealing, and we strive to be part of the solution.

Much of our induction cap sealing is for flexible packaging – pouch fitments (weld spouts) in particular. Because many pouch fitment manufacturers do not line their closures, they do not have the ability to use induction sealing. In many cases, a customer will contact us to discuss a problem they have run into with the liner. When they send us a sample for inspection, we often identify that the issue originated with the process after the closure or container was made.

Our extensive work with induction sealing gives us the insight into how many of these problems can be avoided. Because many closure and container manufacturers do not offer induction sealing, our consulting in this area becomes a major asset in saving customers trouble, time and expense.

Should a customer have a problem with a product’s induction sealing, our staff can make suggestions and even test the product to help troubleshoot the solution. Because we work with the different major liner suppliers, we know their products and procedures and can often help verify that a liner material will be compatible with the chosen injection-molded plastic.

The Key

The key to success with a project is open and proactive communication. When your company, the liner supplier and HQC are all engaged and invested in the product’s best outcome, the chances of success rise dramatically. If you have a product that will include a closure with a liner, be sure to inform us of all materials involved, including the product that will be inside the container, as those contents can influence the lining as well.

HQC induction sealing is yet another way we focus on making your product fully manufacturable and marketable within an optimal budget and timeframe. Contact HQC today to learn more about our induction sealer and induction cap sealing.