Contact us at (630) 820-5550 to see how we can make the difference in your business.

Capabilities

Manufacturing

Getting a quality product to market takes planning, discussion and well-coordinated manufacturing. If you can have all of those vital components with one partner in one location, your chances for success drastically rise.

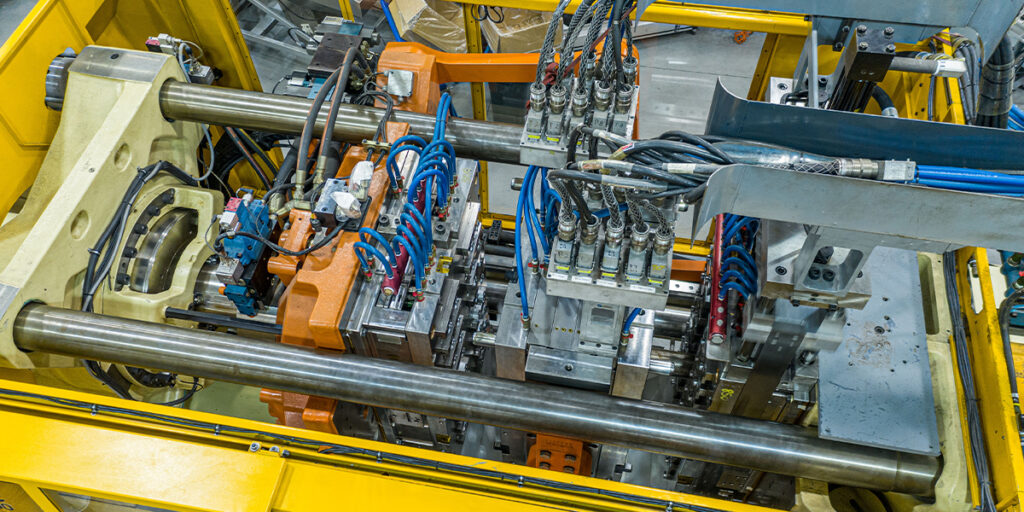

During the last 30 years, HQC has made a point of adding the resources that let you innovate and produce with greater efficiency. Determined to be more than a leader in injection molding, we have diversified our capabilities to serve you as a well-rounded manufacturing company that adds value where you need it the most.

Our experience in many different markets allows us to guide you through manufacturing procedures and solutions including possibilities you may not have been aware of. This gives you an even greater ability to make the choices that best fit your needs.

HQC can manage your project from the concept phase all the way through to the finished product.

Along the way, this includes working to understand your expectations and collaborating closely with you on product design and testing procedures.

Quality standards are also vital to manufacturing, and this is another area where HQC serves you to great effect. Many companies will say they can achieve needed standards for your product, but there’s a catch: They haven’t been audited to confirm their claim. HQC is third-party audited for compliance in manufacturing both food and medical plastic products. This includes review of our facility, our equipment and the work produced by all HQC personnel.

As you know, timing also means everything for your project. Because HQC is a tight-knit, medium-sized manufacturing firm, we eliminate the red tape and bureaucracy that can prevent your product from reaching the market on time.

To See Our Manufacturing Capabilities is to Believe Them

Take a Tour of Our Plant to Discover How We Can Support You

- design support

- 3D modeling

- assembly / kitting

- medical-device assembly

- closure lining

- insert and overmolding

- laser engraving

- product packaging and subassembly

- flexible-packaging prototype

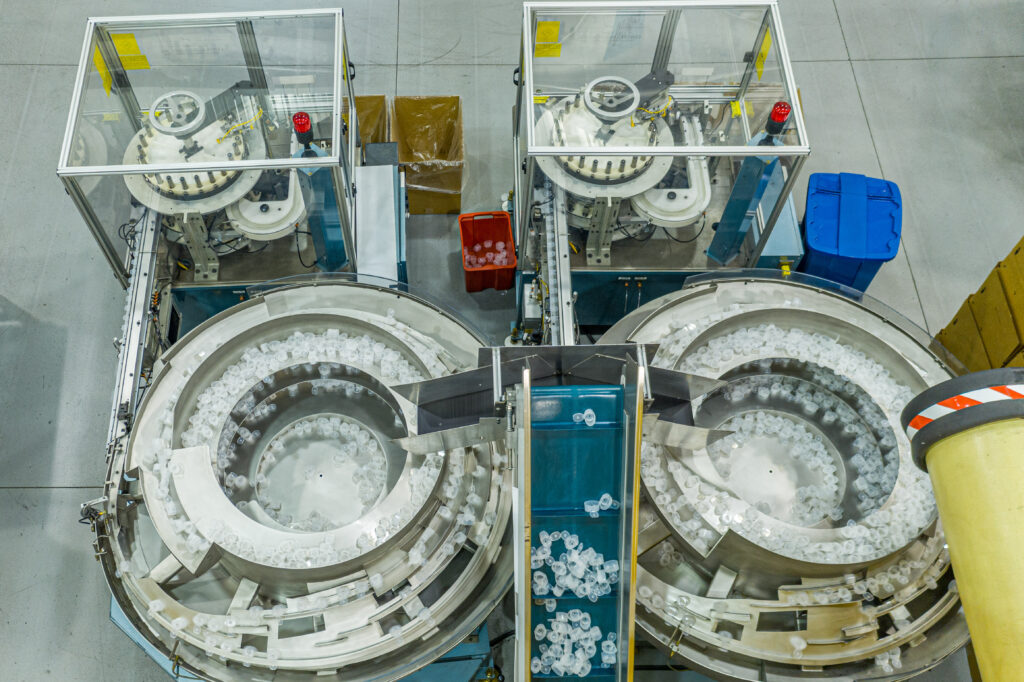

- spout inserting

- capping